Engineering Academy Builds New Kiln Ceramics

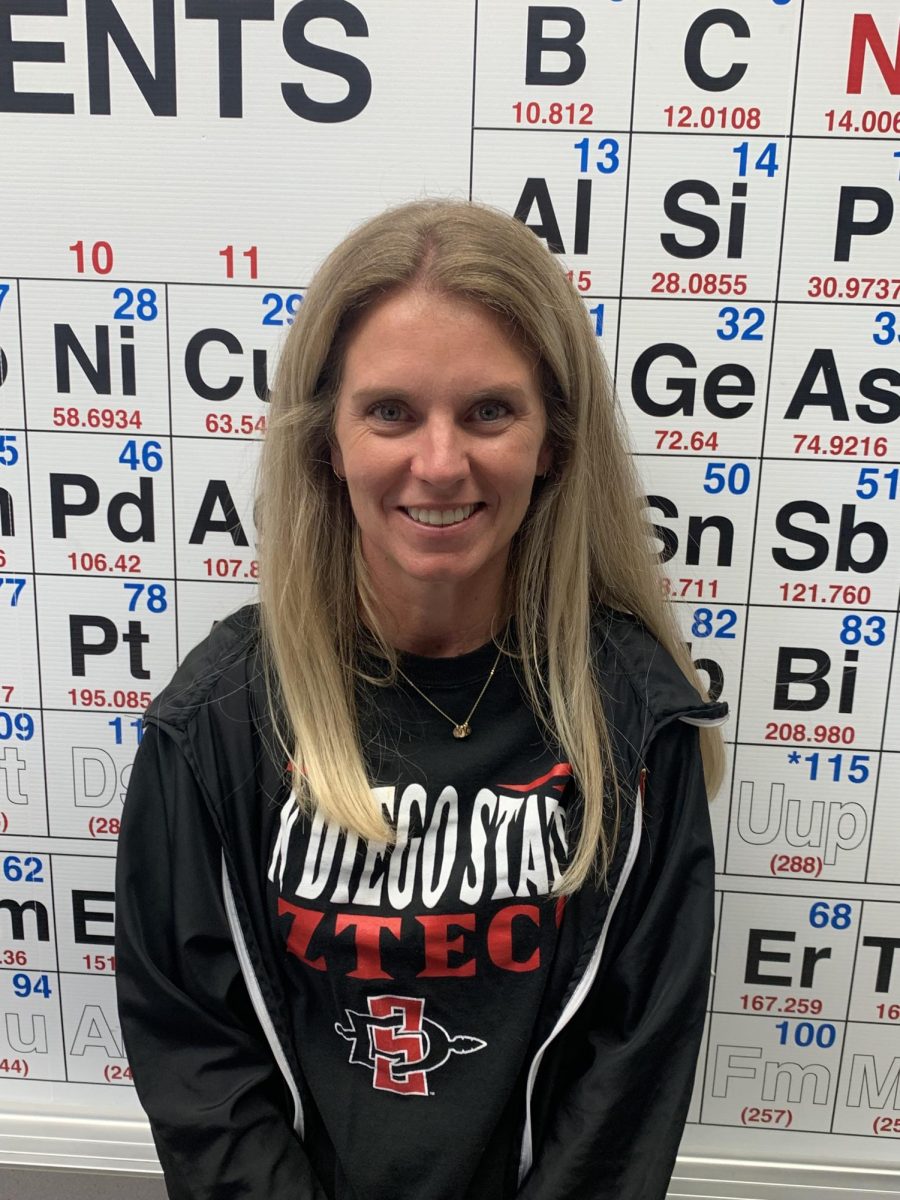

Kevin Kowalski, ceramics teacher, in collaboration with the Engineering and Manufacturing Academy has recently finished the build on the brand new ceramics kiln.

Last year, Engineering and Manufacturing Academy teacher Jeff Wallace and ceramics teacher Kevin Kowalski teamed up to have engineering students built a new kiln for the ceramics courses.

“Engineering and I worked together to design and build it [a kiln]. It has all the great features. It is different from a regular kiln. It has a different type of firing called soda firing. So you put baking soda into the kiln, and it vaporizes and spreads throughout the kiln and then it sticks to the surface of the pots,” said Kowalski.

Kowalski contacted Wallace with a plan about building the kiln. The academy provided the manufacturing experience. There will be a grand opening of the kiln in November.

Alexis Erickson, a senior in ceramics, said, “I was very surprised when I found out there was going to be a new kiln. I am going to use the kiln to fire more clay and I am looking forward to being able to make ceramics faster and to make more.”

“The most challenging thing was to make sure the door was strong and was able to shut equally. A lot of the students like to give back and it also gives a sense of ownership, so the students can look out and say we build that. That is a big part in why we do it. It allows them to give a real-world application on what they are doing and shows the skills they have learned in the classroom and in the lab applies to the outside world,” said Wallace.

“Every student in the classroom has access to put a piece of pottery in it and then the students that helped out building it benefit from that knowledge of problem-solving,” said Kowalski.